A/C filling stations

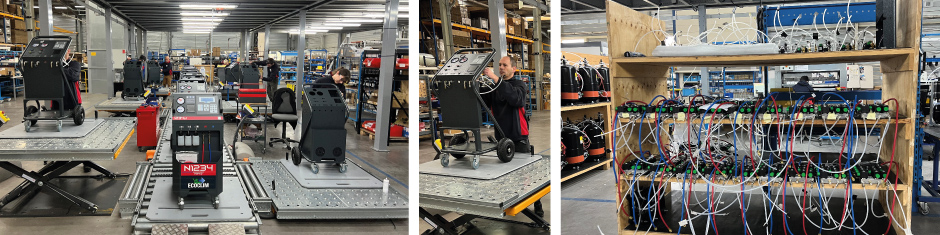

ECOCLIM offers 3 ranges of A/C service stations, 100% made in France, suitable for either workshops or maintenance vehicles.

The WORKSHOP, NOMAD and NOMAD HANDY ranges have been 100% designed by SNDC to provide technicians with a tool that caters for their every need when servicing any kind of A/C system, whether working on road vehicles, agricultural machinery, public works vehicles or aircraft.

The WORKSHOP, NOMAD and NOMAD HANDY ranges have been 100% designed by SNDC to provide technicians with a tool that caters for their every need when servicing any kind of A/C system, whether working on road vehicles, agricultural machinery, public works vehicles or aircraft.

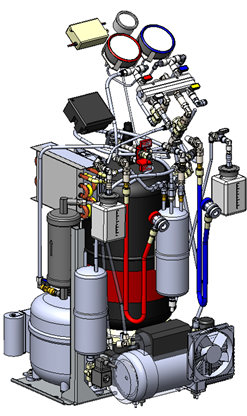

THE WORKSHOP RANGE: 100% WORKSHOP

The WORKSHOP range of A/C service stations is designed for use in workshops servicing vehicle air conditioning systems (cars, vans, lorries, etc.).

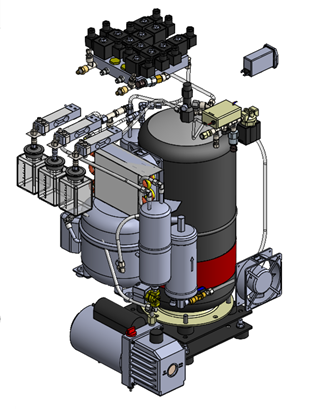

THE NOMAD RANGE: 100% WORKSHOP AND MAINTENANCE VEHICLE

The NOMAD range of A/C service stations is designed to be carried in maintenance vehicles or used in workshops servicing vehicle air conditioning systems (cars, vans, lorries, etc.).

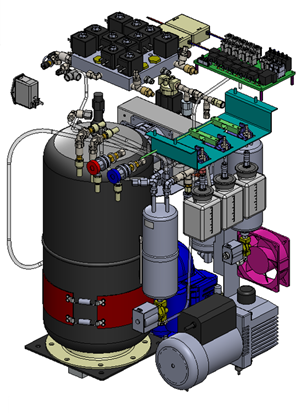

THE NOMAD HANDY RANGE: 100% WORKSHOP AND MAINTENANCE VEHICLE

The semi-automated NOMAD HANDY range of A/C service stations is designed to be carried in maintenance vehicles or used in workshops servicing vehicle air conditioning systems (cars, vans, lorries, etc.).

Dedicated to refrigerants :

The WOKSHOP, NOMAD and NOMAD HANDY ranges guarantee :

- R134a

- R1234yf,

The WOKSHOP, NOMAD and NOMAD HANDY ranges guarantee :

- ease of use,

- ease of use,

- reliability in the harshest working environments.

Les Tutos ECOCLIM

A complete guide to servicing A/C systems, all at your fingertips.

From getting started to configuring parameters, these tutorials will guide you through each step.

From getting started to configuring parameters, these tutorials will guide you through each step.

WORKSHOP Mini-series:

- Introducing the W134 A/C service station

- Getting started with the W134 A/C service station

- Using the W134 A/C service station in automatic mode

- Using the W134 A/C service station in manual mode

- Topping up the refrigerant in an A/C circuit.

- Performance testing with a test vehicle

- Nitrogen leak testing with the W134

- Admin made easy with the W134 job history feature

- The W134 Service menu

- A well-configured tool ensures a job well done

ECOCLIM TECHNICAL SERVICE FOR YOUR EVERYDAY PEACE OF MIND

Whether it's commissioning, maintenance or repairs, our after-sales service technicians are available to work on-site at any workshop in France.

ECOCLIM offers technical assistance both on-site and via our hotline:

ECOCLIM offers technical assistance both on-site and via our hotline:

- Bespoke commissioning service

- Annual maintenance

- Repairs

- Courtesy station if required

ECOCLIM EXPERTISE

After more than 37 years as an Original Equipment Manufacturer (OEM) of Heating, Ventilation and Air Conditioning (HVAC) systems, SNDC has acquired unique expertise in the design of tools for handling refrigerant fluids.

Unbeatable weight precision (patented):

SNDC's patented weighing technology offers unbeatable precision for use in workshops or on maintenance vehicles operating in even the most challenging conditions (tolerating a maximum tilt of up to 12°). It allows you to charge systems with a precision of ±10 g, whatever the circuit capacity. The unit weighs all the refrigerant in the separator and condenser and saves all job data, so you can be sure of a reliable fluid balance.

SNDC's patented weighing technology offers unbeatable precision for use in workshops or on maintenance vehicles operating in even the most challenging conditions (tolerating a maximum tilt of up to 12°). It allows you to charge systems with a precision of ±10 g, whatever the circuit capacity. The unit weighs all the refrigerant in the separator and condenser and saves all job data, so you can be sure of a reliable fluid balance.

Proven reliability (patented):

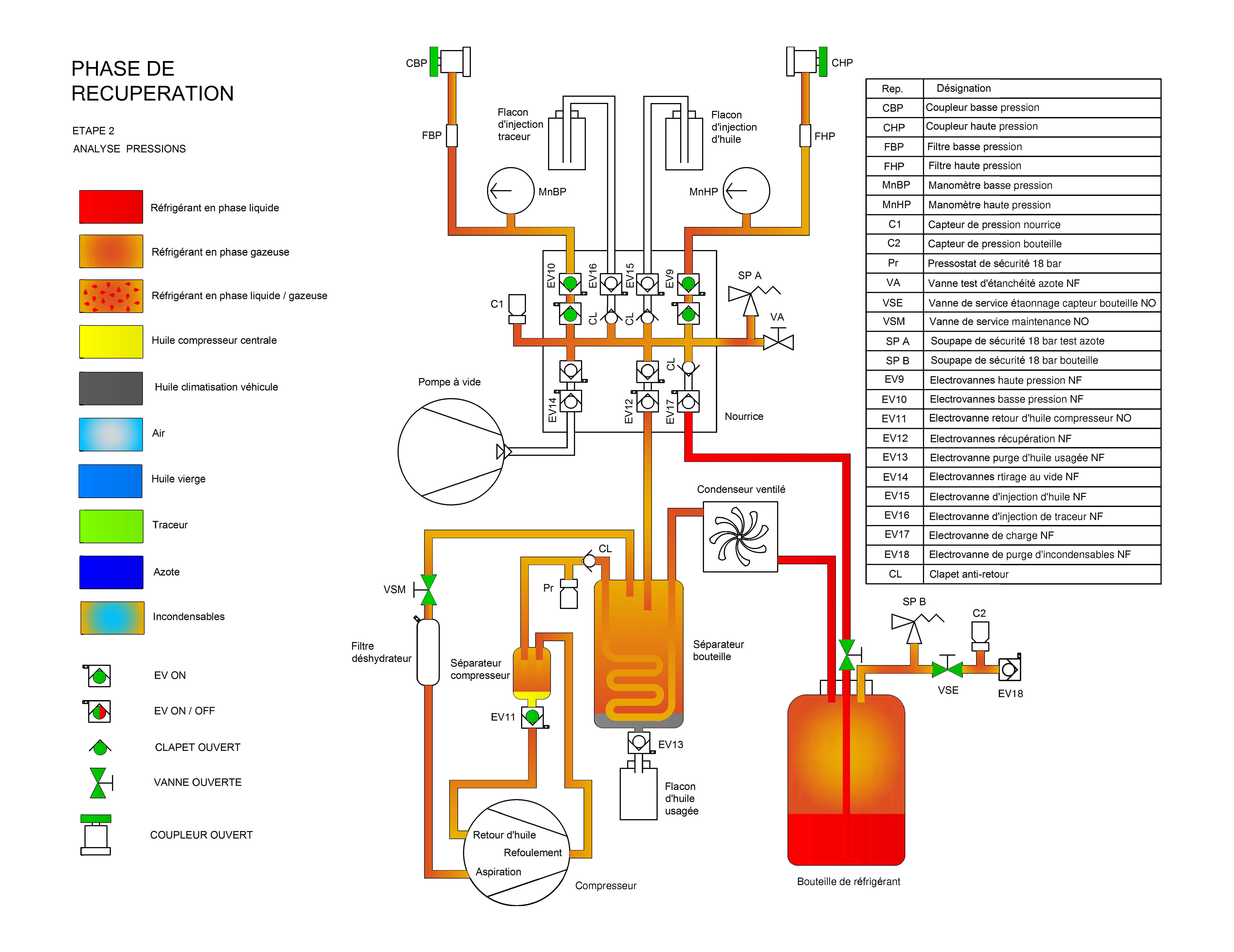

SNDC’s patented distributor block is unique on the market. Instead of using traditional anti-return valves, the double solenoid valve design developed by SNDC engineers eliminates any risk of unintended degassing. This guarantees that the different circuits are completely isolated at all times. It also ensures that the station can be used in complete safety in temperatures up to +45 °C, for even the toughest working environments.

SNDC’s patented distributor block is unique on the market. Instead of using traditional anti-return valves, the double solenoid valve design developed by SNDC engineers eliminates any risk of unintended degassing. This guarantees that the different circuits are completely isolated at all times. It also ensures that the station can be used in complete safety in temperatures up to +45 °C, for even the toughest working environments.

Full regulatory compliance:

ECOCLIM stations meet the following certifications:

Unique features:

Basic functions for the extraction and recharging of refrigerant fluid, including fluid recovery, recycling and pump-out, vacuum leak testing, and oil and fluid charging. ECOCLIM stations also offer essential capabilities for certain repair tasks, such as:

ECOCLIM stations meet the following certifications:

- (EMC) Directive 2014/30/EU

- EN 61000-6-1 and EN 61000-6-3, 2007

- EN 61000-6-3/A1, 2007

- Pressure Equipment Directive 2014/68/EU

- A2L Refrigerant Fluid Handling Tool Safety

- Machine Directive 2006/42/EU

- NF E35-421 standard on recycled fluids

Unique features:

Basic functions for the extraction and recharging of refrigerant fluid, including fluid recovery, recycling and pump-out, vacuum leak testing, and oil and fluid charging. ECOCLIM stations also offer essential capabilities for certain repair tasks, such as:

- Nitrogen leak detection at 15 bar of pressure.

- Ecological, economical and efficient flushing in liquid phase, obligatory when replacing a compressor or condenser.